Increase machine availability and productivity by gaining visibility into the production floor

3d Signals for the Machine Tool Industry

Trusted by:

3d Signals helps machinery companies like yours:

See what's happening on the production floor. Track performance and output to optimize production processes and monitor KPIs

Improve Productivity

Identify idle times and increase machine working hours with your existing resources

Increase Competitiveness

Reduce costs and maximize production to gain an advantage through data-driven decisions

How machine tools companies use 3d Signals:

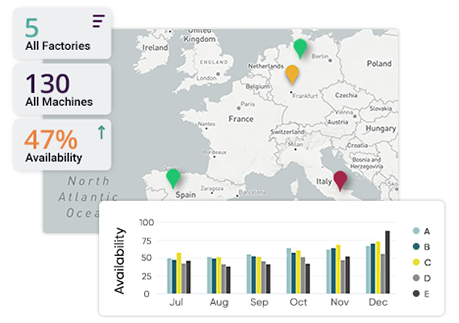

PUBLIC VIEW

FULL TRANSPARENCY

Ensure machine availability for continuous, non-stop production

LIVE VIEW

REAL-TIME VISIBILITY

Control & manage production tasks on the go

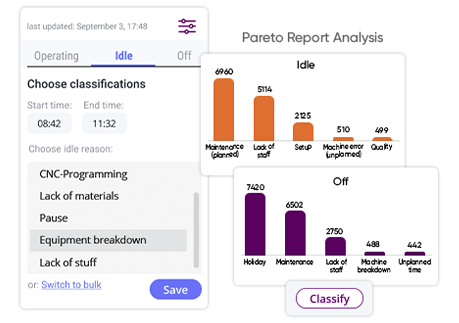

MACHINE VIEW

DOWNTIME OPTIMIZATION

Identify bottlenecks and optimize customized or mass production by classifying idle and off reasons

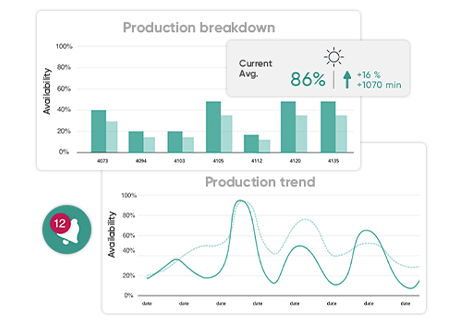

REPORTS & ALERTS

DATA-DRIVEN DECISION MAKING

Detailed business intelligence and actionable insights

MOBILE

WHEREVER, WHENEVER

Mobile friendly views for a 24/7 control