Reduce operating costs

by identifying bottlenecks

with machine monitoring

Customer stories:

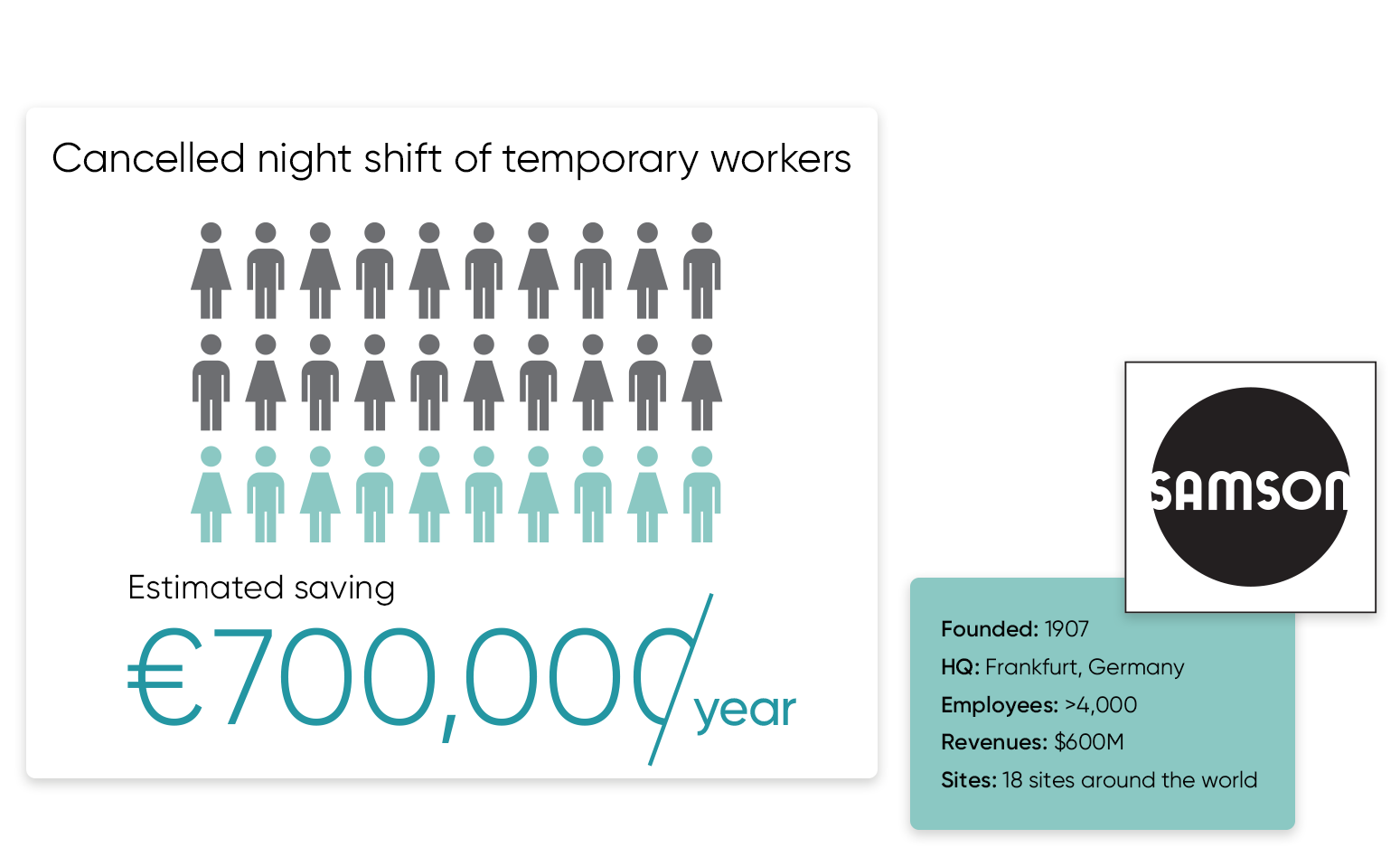

€700K/YEAR WORKFORCE COST REDUCTION

Real-time monitoring improved the efficiency of the morning and afternoon shifts.

The night shift, carried on by temporary, less experienced, and more expensive employees, was eliminated

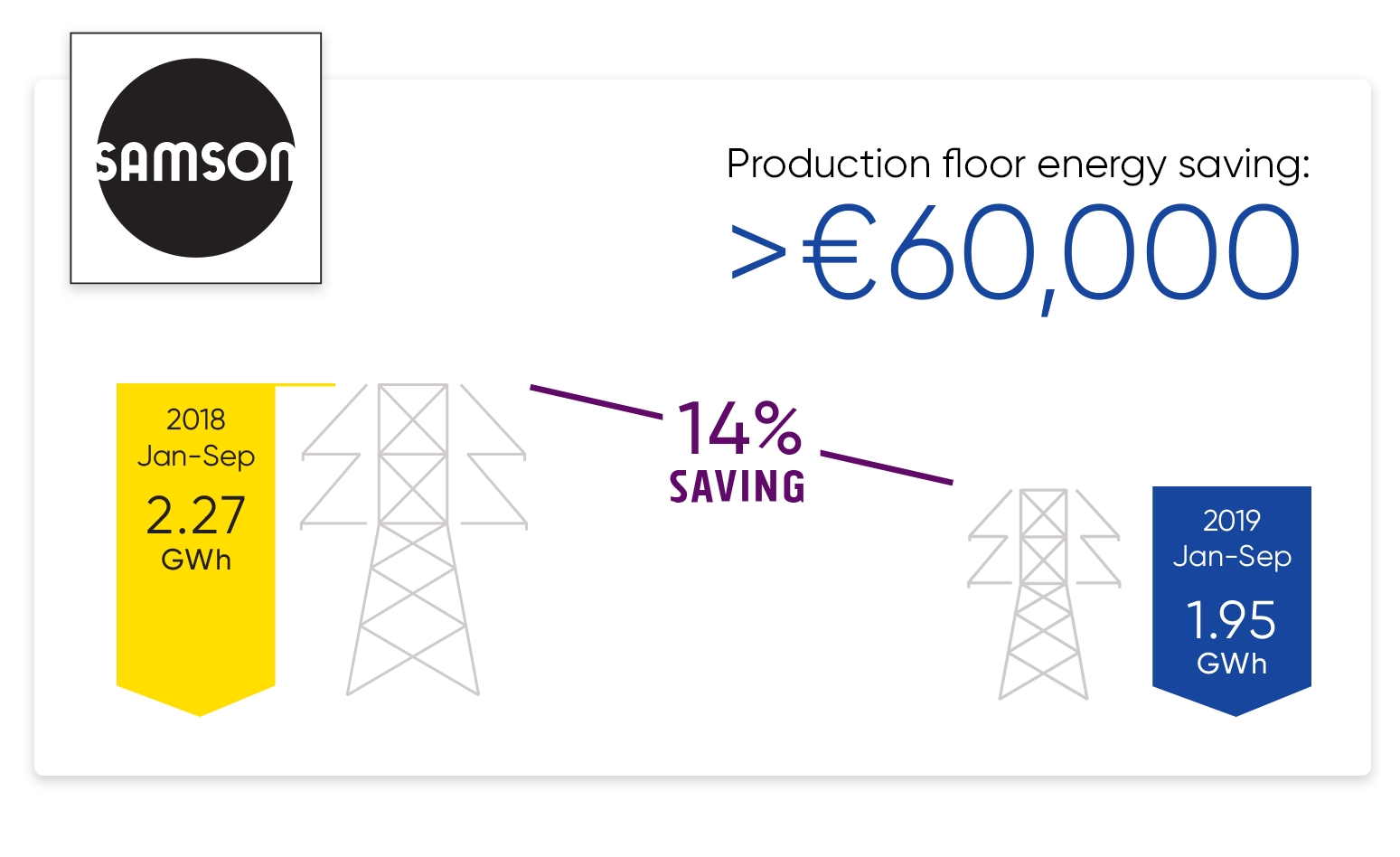

14% ENERGY COST REDUCTION

Energy consumption reduced by preventing idle machine periods.

Machines are either operating and manufacturing parts or turned off