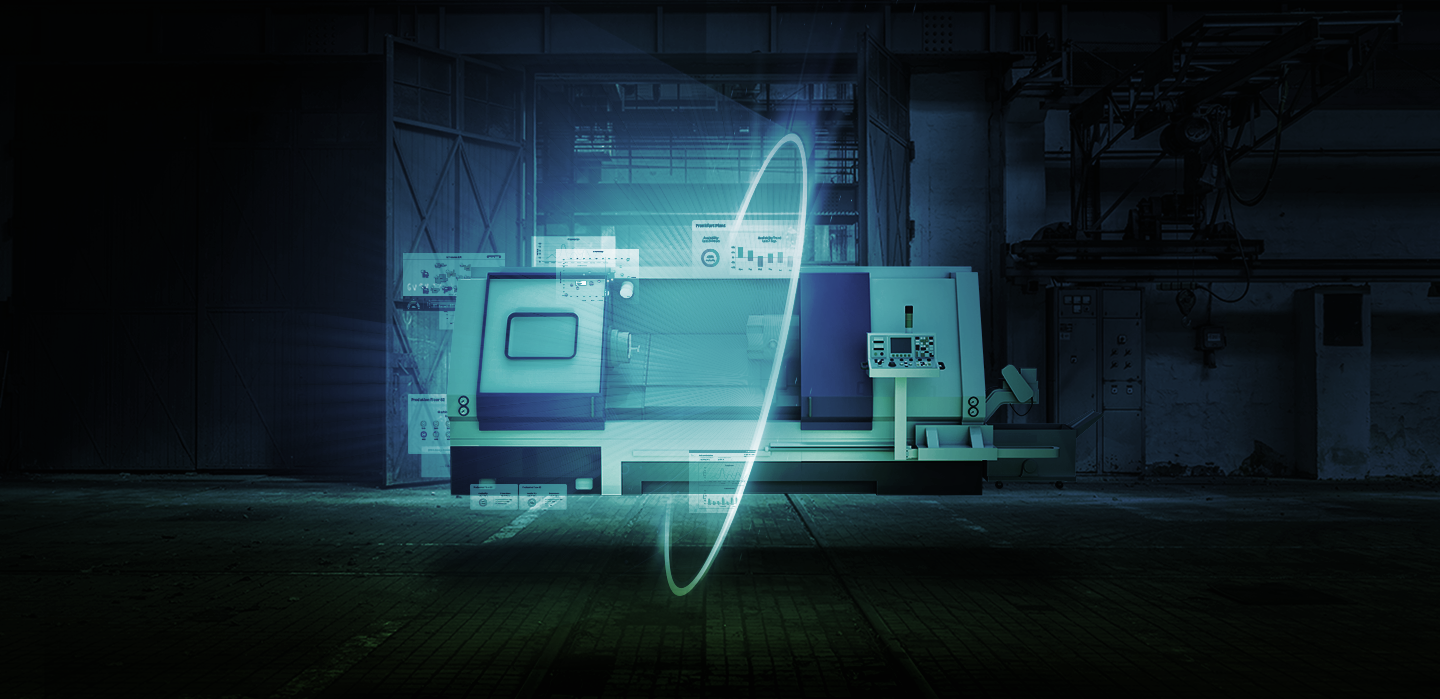

We are 3d Signals. We digitalize and monitor machines of all types, makes, and models. Sometimes, it comes back to bite us. As part of the R&D team, we got a mission to survey a very unique and rare type of machine – an Electro-Chemical Machine (ECM). We are acquainted with a lot of machines, old and new, but this was our first ECM. We took the challenge head-on.

This was obviously during the BC times (Before Corona), when we could fly to any destination. After landing in Frankfurt, we drove to the factory, with a quick stop in a rural area restaurant. At first glance, the factory looked quite ordinary. We knew beforehand that the factory produced very special parts in a unique way with tailor-made machines. But, the customer forgot to mention how old the machines were. Needless to say, no other company was able to monitor these machines. As we saw the machines, we realized that they are even older than the oldest person in our team.

The machines looked quite “simple” at first glance, with no visible anomalies. The customer representative that accompanied us told us that each machine consumes 10000A. Nothing in the electrical cabinet seemed to be able to handle a fraction of this current. After double-checking with our guide, we asked him where such a current might come from. That is when he took us to the cellar. There were tubes and chemical filtration baths that looked like the beginning of a horror movie. Additionally, there were hundreds of signs that warned of the strong magnetic forces, produced by the high currents in the metal beam conductors that went to the factory floor. And then we realized that the machine does in fact consume 10000A.

Early experiments of the electrochemical process for metal processing were done in 1929, but only in 1959, the first commercial process was established. The 1960s and 1970s turbine industry searched for methods to process strong alloys with complex shapes. In the ‘80s great improvements were made with new types of electrolytes and higher currents. Now ECM machines are used to produce turbine blades, surgical instruments, etc.

Electrochemical machines dissolve the material precisely with an electrochemical reaction. The mold, which is a negative of the desired shape, is moved toward the workpiece. When the distance between the mold and the workpiece (working gap) is tenths of micrometers, the reaction erodes the workpiece. It takes a considerable amount of current flow. Some machines consume as much as 40000 Amperes. It is equal to the current of 3500 average American households. The power supply cables have to be very thick, and these are the beams that we saw in the cellar.

During the chemical process, the electrolyte is dissolved in water and decomposes into positive and negative ions. A chemical reaction takes place in two places simultaneously: on the mold and on the workpiece. The reaction depends on the electrolyte type, mold, and piece composition. Let’s take a closer look at an example reaction, so you could build such a machine in your garage.

Let’s take NaCl (salt) with water as an electrolyte, Fe (iron) for the workpiece and connect it to an anode, and Cu (copper) as the mold and connect it to a cathode.

NaCl -> Na+ + Cl–

H2O -> H+ + OH–

Na+ + OH– -> NaOH it is very important to keep the water:salt ratio

Fe -> Fe++ + 2e–

Fe++ + Cl– -> FeCl2Fe++ + OH– -> Fe(OH)2

Two insights can be gleaned from the formulas. The first, hydrogen ions accept electrons on the cathode side and are released as hydrogen gas. The second, the mold does not take an active part in the chemical reaction and astonishingly, it does not erode and can be used infinitely.

In the 1980s the precision was about 20-50 microns and surface roughness of 0.2 microns. The precision depends on the working gap between the mold and the workpiece. The lower the gap the better the precision. There are two challenges with small gap processing. The first, the hydrogen gas does not conduct electricity, we must remove it as fast as we can. The second, the electrolyte solution temperature rises rapidly and we must keep it below the evaporation point.

The solution for small gaps with high precision processing is to strongly agitate the electrolyte solution. Modern machines achieve this by vibrating the mold. When the gap is at minimum the current spikes, and very precise processing takes place. Then, when the gap increases, the gases and dissolved materials are flushed out easily. It happens repeatedly hundreds of times per second. This way precision of 1-5 microns is achieved, with surface roughness of hundreds of nanometers.

We figured that the key to monitoring the operation of the machine is to monitor its high currents. Current that flows through the conductor generates a magnetic field, which can be calculated using the Biot-Savart law. By measuring the magnetic field, perpendicular to the conductor, we would be able to measure the amount of current that dissolves the workpiece in an objective and non-invasive way. We estimated the order of magnitude of the current the machine uses and searched for the sensors in the required sensitivity range. Between the magnetoresistive, Hall, and inductive coils, the obvious choice was Hall sensors. They are cheap, durable, and can sense constant (DC) magnetic fields.

We designed a complete sensor to connect to our Data Acquisition System (dEdge device), and performed the field tests. After adding a little bit of algorithmic magic,the factory managers could see, for the first time, the machine utilization in real time. All in all, it took us about 3 weeks.

In the photo you can see the copper beam which conducts the current and the sensor we used (the circle in the middle).

The customer was surprised that we were able to monitor even these machines, and asked to install our solution on all the machines he had.

We call this digitalization, he calls this magic.