With constantly updated restrictions and limitations imposed due to the COVID-19 pandemic, manufacturing managers are presented with new challenges every day. Available data and remote visibility become crucial for the continuous operation of manufacturing plants.

The most recent one, social distancing (SD), is especially difficult to implement on factory floors, where employees work in a single space (no corner offices…). Add to that, instances when the managers themselves are quarantined or self-isolated and are forced to work remotely.

How do you manage manufacturing from quarantine and make sure that your vital employees remain safe and follow social distancing instructions while keeping productivity levels high and minimizing the financial impact on your business?

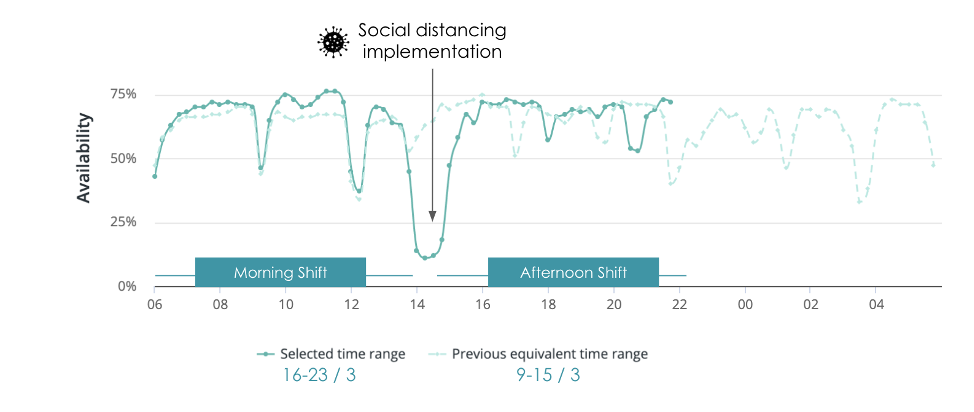

In Germany, Frankfurt-based valve manufacturer SAMSON AG implemented social distancing through a 1-hour break between shifts (2pm-3pm) to prevent physical contact between employees of the morning shifts and those of the afternoon shift.

The graph below, showing the average daily availability this week compared to the previous week, is used by managers in self-quarantine to make sure that both:

It is evident from the graph that even though shifts are shorter due to SD, and managers are working remotely, availability levels remain high and productivity KPIs are achieved.

Also evident from the graph are the fewer common breaks employees take, mainly during the afternoon shift, an indication that employees are obeying SD and protect themselves and their colleagues.

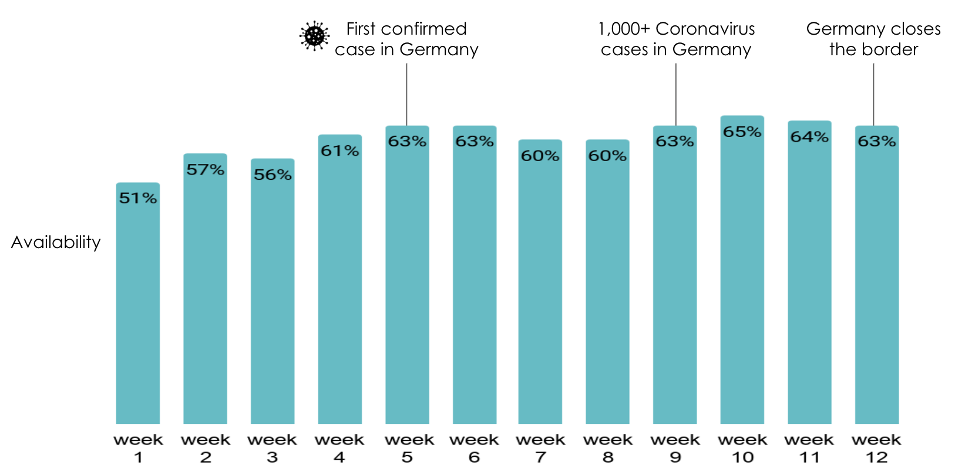

Looking at the availability levels since the beginning of 2020, the graph below shows how SAMSON AG managed to keep machine availability high throughout the coronavirus outbreak, and again when social distancing was implemented in its Frankfurt factory (between weeks 10 and 11).

SAMSON AG uses the 3d Signals cloud-based monitoring platform that allows complete visibility into machine availability through non-invasive sensors installed on each machine.

To gain remote control over your production floor, contact us.