KFAR SABA, Israel, April 20, 2022 – 3d Signals has released a new Energy Efficiency Solution as part of its manufacturing sustainability portfolio that helps manufacturers of all sizes to increase productivity, lower costs, and decrease carbon footprint.

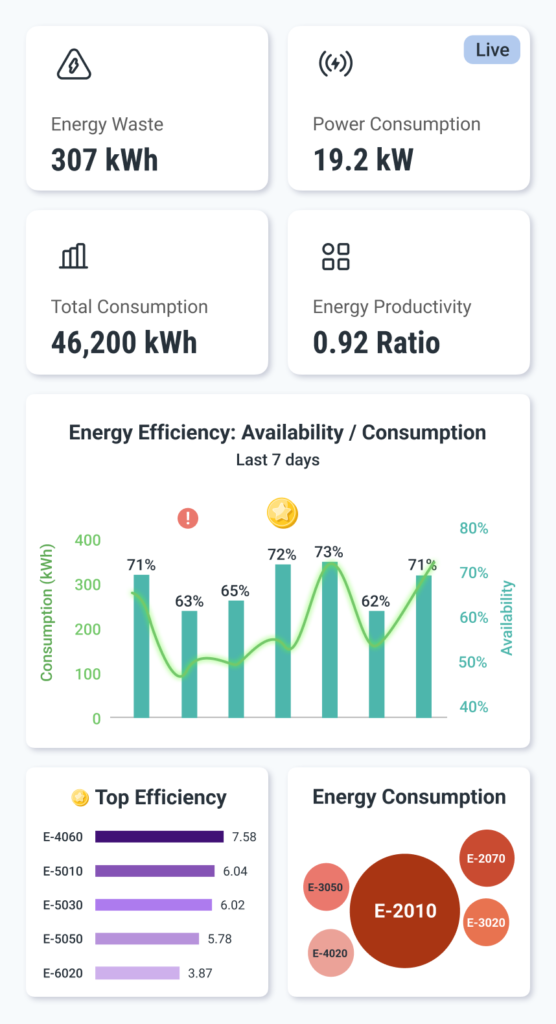

The new 3d Signals’ Energy Efficiency Solution offers a unique proposition of visibility in real-time and analytics with insights correlation between machines’ availability and its energy consumption.

Manufacturers will be able to use the solution to:

“We’re giving manufacturers a simple way to quickly reduce their production costs, reduce the CO2 footprint of their products, and prepare for stricter green regulations,” says CEO Ariel Rosenfeld. “It’s a solution that’s set up in days and works on any machine. We are delivering smart manufacturing for a better world.”

The new 3d Signals Energy Efficiency Manufacturing Solution compliments

3d Signals’ Asset Monitoring solution already used by manufacturers to increase productivity and reduce production costs. Using the Energy Efficiency solution enables manufacturers to make data-driven decisions for energy efficiency and profitability.

“3d Signals helped us to significantly increase asset utilization and consequently save > €1M annual costs in production. Considering rising energy prices and strict EH&S regulations, we have defined our strategic path towards net-zero emissions and carbon-neutral production,” says Dr. Andreas Widl, CEO of SAMSON AG, a leading manufacturer of industrial valves, headquartered in Frankfurt, Germany. “Using 3d Signals’ Smart Technology on our shop floor has allowed us to increase overall equipment efficiency and save on energy costs in the shortest time possible.”

According to data released by Eurostat this month, energy prices in Europe rose 45% in March from a year ago – and prices are expected to remain high. This hits European manufacturers especially hard as factory machines consume a lot of energy.

A December 2021 US Energy Information Administration report finds that 48% of US manufacturers have actively explored ways to reduce energy consumption – but their efforts have focused mostly on facility lighting and HVAC efficiency.

3d Signals’ new solution will help manufacturers now focus on increasing the energy efficiency of their production floors. By capturing accurate insights about each machines’ availability and energy digital data, 3d Signals’ software pinpoints ways to increase energy productivity and ensure each kWh is not wasted on unplanned shifts or idle states.