Travis Ziebro of Punchlist Zero sat down with Chief Operations Officer, Galia Kedmi, to discuss how 3d Signals helps manufacturers transition to become a factory of the future.

Travis Ziebro: Tell us a bit about 3d Signals. How was the company formed? What is its mission?

Galia Kedmi: We were founded in 2015 with the goal of simplifying and accelerating the digital transformation of manufacturers to Industry 4.0. We believe that what can be measured can be improved. One challenge for manufacturers is digitalizing their production floors.

Factories have a mix of old machines and new machines from various vendors that perform different functions. Because of this, many manufacturers collect machine production data manually. It’s a time-consuming process and the data is often incomplete. It’s the incompleteness of the data that makes an important difference. These seemingly “small” unreported omissions quickly add up. So the data picture you’re getting is actually incomplete. And your planning assumptions will be faulty.

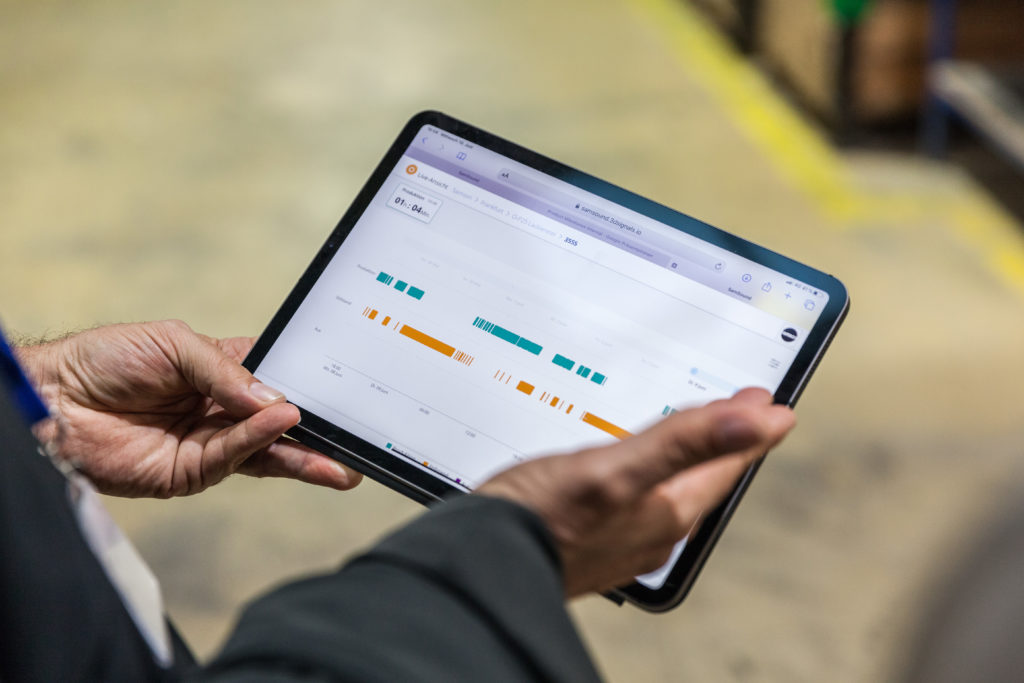

We provide a solution that works with any machine and collects information automatically and continuously, so everyone – from the CEO to machine operators – can have real-time and accurate visibility into the production floor. Data is then run through our AI-based Asset Performance Monitoring platform to transform the data into insights to improve productivity. Customers have told us our solution strengthens their competitiveness and has helped ensure job security across their organizations.

For example, one of our customers, Eckart Hydraulics, increased productivity by nearly 30% within four months of installation just by showing accurate real time machine status on large screens visible to all employees on their floors. That’s with no changes in their processes, staff or equipment.

Travis Ziebro: To solve production issues, the first step for General Managers is usually to hire a Lean Consultant to evaluate processes. Does 3d Signals partner with these consultants or replace that process entirely?

Galia Kedmi: Lean consultants can be incredibly valuable for businesses. They can help reduce time spent on complex tasks, they can analyze demand versus the output for your product, and they can suggest better processes by replicating methodologies used by top performers. Their work takes time, and requires accurate data to be effective.

Streamlining production based on trimming excessive downtime (caused by frequent intervals of unproductive time), we would argue that this is best done through sensor-based monitoring data. The sensors provide accurate and complete data. Moreover, the insights we can provide are visible within hours of installation. Whereas lean consultants would need months collecting and analyzing data before they could make recommendations (which are limited to the time-period in which the data was collected). That’s too slow for the many dynamically changing situations faced by manufacturers today.

Additionally, our approach provides a holistic view of the entire production process, explaining bottlenecks and uncovering inefficiencies. The insights we provide come from real-time data and are constantly being analyzed and enable customers to make real-time decisions that increase throughput.

״Our approach provides a holistic view of the entire production process, explaining bottlenecks and uncovering inefficiencies.״

Galia Kedmi

Travis Ziebro: On your website you tout “Full Coverage” of any machine from any era. I can’t help but to think of dusty bandsaws paired alongside ultra modern CNC machines. How do you make sure the 3d system works well with both ancient machinery and highly digitized machines?

Galia Kedmi: Yes, and that’s completely accurate – the average production floor consists of multiple machines from a variety of vendors, models, and ages. This is the main challenge for manufacturing digitalization. We saw a gap in the market where only 8% of the 60 million machines worldwide are connected to a network. The result is low levels of machine utilization, low OEE (Overall Equipment Effectiveness, a measure of machine’s availability, performance, and quality), and a loss of billions of dollars due to unplanned downtime and unnecessary machine purchases.Our solution works with both antiquated and highly digitized machines. We install non-invasive sensors to machine exteriors – this makes the sensors machine-agnostic. Some solutions from other vendors focus only on monitoring power signals. This type of sensor leaves a lot of machine activities unmeasured. Whereas, we have more than a dozen different sensors, for greater machine-specific measurement accuracy. They capture a variety of information about machines. Next we utilize a cloud-based AI platform that real-time analyzes sensor data and enables immediate visibility into production floor activity. We can digitize an entire production site in a matter of days and that data can be used by stakeholders from day 1. It’s really quite remarkable.

“We believe what is measured is improved.”

Galia Kedmi

Travis Ziebro: Tell me about some of the 3d Signals most successful engagements. Any particular story that your team is most proud of?

Galia Kedmi: In the last 50 years, has there been a more disruptive time for manufacturing than during COVID-19? When the world shut down, we are very proud that we grew during very uncertain times.

Manufacturers today need to react quickly to fast-changing situations. During the COVID-19 pandemic, accurate real-time data and remote visibility became crucial for the continuous operation of manufacturing plants. Proven solution effectiveness became a game-changer. 3d Signals gave our customers the ability to manage their manufacturing remotely with full visibility to the organizations’ KPIs globally while keeping productivity levels high.

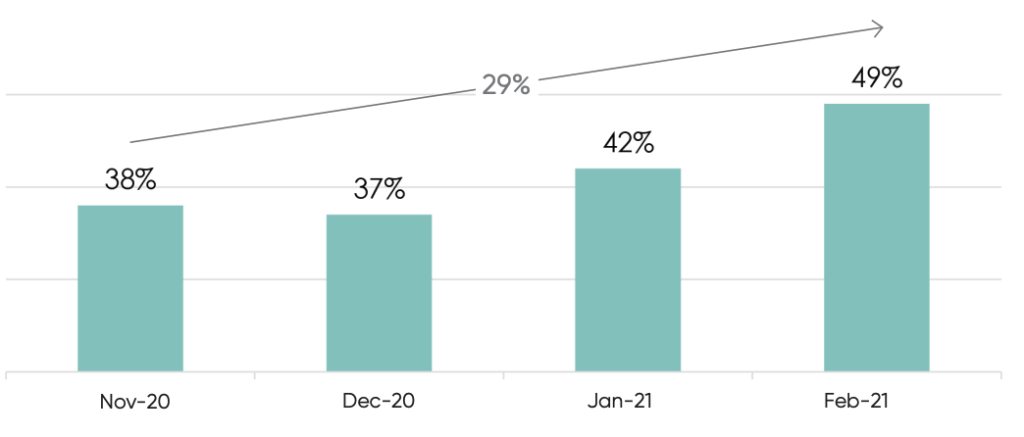

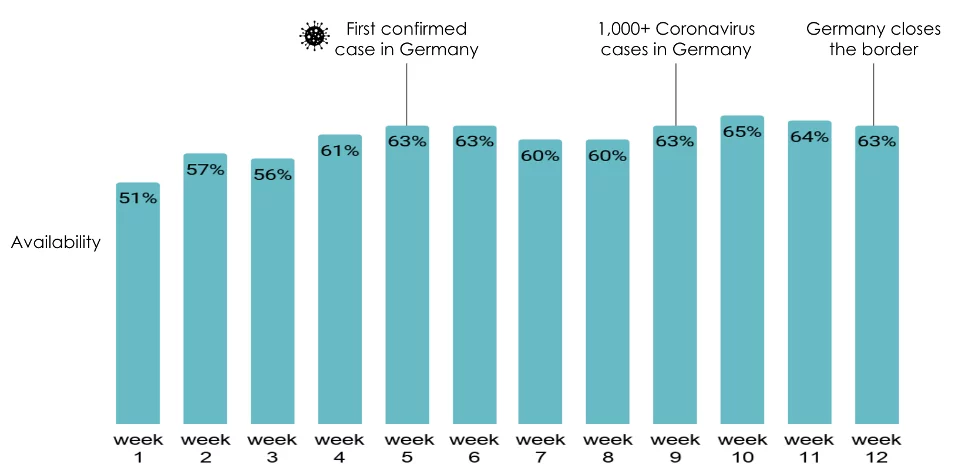

While factories faced reduced output due to social distancing restrictions, our clients maintained output due to the operational insights they gained from our solution — even while they were losing 1 hour of production time required to prevent physical contact between employees during morning and afternoon shift changes.

One would expect that losing 1 hour of production between shifts for months on end would have a dramatic effect on the company’s bottom line. The graph below shows how our client SAMSON AG managed to keep machine availability high throughout the coronavirus outbreak, and again when social distancing was implemented in its Frankfurt factory (between weeks 10 and 11).

Travis Ziebro: One surprising finding in this data rich era is that manufacturers sometimes complain that they receive too much data – which ends up overwhelming servers and paralyzing decision makers. How do you ensure asset owners receive only the most pertinent information and not a deluge of numbers?

Galia Kedmi: Agreed. Too much data can lead to “analysis-paralysis”. It also leads to greater anxiety and indecision. Studies in psychology and neuroscience reveal that analysis paralysis takes a far greater toll on your productivity and well-being than just lost time.

While we have a lot of data points showing a wide range of information in customizable reports, we’re constantly optimizing reports to remove clutter. Our success depends on our customers’ success. We need to provide data and insights that our customers can use to improve their business KPI’s from day one.

For example, our client the ROTHENBERGER Group was able to add an unplanned €4M Purchase Order into their already committed production schedule. They could confidently add the job because first, they had already adopted more efficient production processes designed using insights from the accurate data our sensors gave them. Secondly, they could more accurately forecast requirements and schedules using better production metrics based on accurate and complete machine production data. This would not have been possible before.

Travis Ziebro: Let’s flash forward another decade. How has 3d Signals’ mission become more fully realized?

Galia Kedmi: We anticipate that over the next decade as we add customers, we will provide more solutions and will sharpen our data collection and analysis capabilities. We want to help manufacturers profit from the explosive growth of data available to them.

We want our insights to become more impactful and are developing solutions that will support manufacturers to achieve sustainable practices. Our customer Samson AG has successfully reduced their energy consumption and saved more than €70,000 a year by preventing idle time.

We believe that in today’s manufacturing marketplaces operating without accurate, real-time continuous data about production processes and production floors leaves you at a competitive disadvantage.

In addition to providing insights to individual clients, we’ll be able to analyze results from across our client base to provide recommendations based on regional, national and global manufacturing trends.

As I mentioned before, we believe what is measured is improved. By measuring manufacturing data across geographic regions and types of business – even types of machines – we can offer powerful business intelligence to give our customers strategic and tactical competitive advantages.

—–

Punchlist Zero serves as a resource for engineers. To read more about, Punchlist Zero, click here: https://www.punchlistzero.com/