Manufacturing is evolving at a staggering pace, with connectivity taking modern and advanced factories to a whole new level. Smart Factories are manufacturing environments where connected machines, processes, and ecosystems can be optimized by leveraging data analysis. Industrial IoT (IIoT) is the key that is now unlocking all of the hidden potential.

But how do smart manufacturing and smart factories work in reality? Let’s take a closer look.

The modern manufacturer is now looking at narrower profit margins due to factors such as growing competition and price pressure, in combination with increasing supply chain and labor costs. Executives have no manual solution to extract more from their production lines. Machines and humans, as good as they may be, will only get you so far. Enter Industry 4.0 and asset performance monitoring.

Let’s take a quick look at the evolution of manufacturing turned smart manufacturing, and learn more about the fourth industrial revolution, commonly known as Industry 4.0. We will also explain how you can take the first step towards creating your own smart factory.

Prevailing manufacturing models were impressive back in the day when efficiency requirements were not high, or were even undefined in many cases. But this manufacturing strategy, or lack thereof, can no longer help maintain sustainable growth in today’s uber-competitive market. The mass globalization of manufacturing has brought in new players from Asia that have amplified the need for Smart Factories and optimized smart manufacturing pipelines.

Companies now need to ensure optimal quality in minimal time at the lowest cost possible, while making sure that bottlenecks are eliminated and labor costs are reduced to a minimum. The old models, in which market leaders were setting the market price, simply can’t be relied upon anymore. This is creating new manufacturing challenges across all verticals.

Machines – Companies are using complex pieces of machinery to deliver products on time. However, every machine has dozens (or sometimes hundreds) of components that can break down at any given time, leading to unwanted operational halts. Not having real-time monitoring of product quality and quantity can lead to serious financial and brand damage.

Human Resources – Today’s factories rely heavily on two primary assets – their machines and the people who operate them. Machines need to work faultlessly and the staff has to be error-free for optimal results. This is simply not a realistic scenario. Existing manufacturing processes that rely solely on manpower are not capable of creating streamlined pipelines for smooth end product delivery with fast time-to-market.

Diversified Portfolios – More and more companies today are creating multiple products with limited resources. The machines are the same and so are the people handling them. Unlike the past where there was a single process for all orders, diversified product portfolios make it extremely hard to optimize manufacturing processes and maximize product quality.

Manufacturing Complexity – Flexibility is a big requirement that manufacturers are failing to meet today. Market demand is extremely fluid and is affected by a wide range of factors – economical drifts, political developments, and other reasons such as the most recent Covid-19 pandemic, which has also had a direct effect on consumer demands and requirements.

Furthermore, these factors influence raw material supply chains. The response times to these changes needs to be minimized, something that traditional models can’t do due to their rigidity and lack of actionable insights.

These are just a few of the limitations and shortcomings of the existing manufacturing model, which can no longer allow companies to make sustainable profits and release reliable products to the market. Executives need to know what is going on in real time to respond faster to problems and create a sustainable manufacturing pipeline and optimize supply chain management. This is where Industry 4.0 comes in and introduces the smart factory.

The solution to overcome the above-mentioned limitations is industry 4.0. This industrial revolution is about connectivity and the digital transformation of the manufacturing and the value creation processes. This involves the use of Industrial Internet of Things (IIoT), Machine-to-Machine (M2M) communication, Machine Learning, Artificial Intelligence (AI), and many other data-driven and digital channels and platforms that eventually create the ‘Smart Factory’.

Manufacturing as we know it, will not be the same at the end of the upcoming decade. IIoT adoption will probably add 700 billion USD to the German GDP by 2030.

It all started in the 19th century with the invention of the steam engine and the replacement of home manufacturing by factories in Great Britain. Industry 2.0 was based on the integration of electrical devices to mobilize mass assembly lines (during World War II). The current Industry 4.0 revolution is the continuation of Industry 3.0, which involved the computerization of machines and automation of production processes to significantly reduce the dependence on human intervention.

The Industrial Internet of Things (IIoT) is powering Industry 4.0. In a nutshell, it’s the incorporation of the advances made in mobile tech, cybersecurity, and M2M capabilities into the smart manufacturing ecosystem. This is made possible by using “smarter” machines that can hook up to a single network and provide a plethora of operational information to optimize the entire manufacturing process and create a smart factory.

Top benefits of Industry 4.0, or smart factories, include:

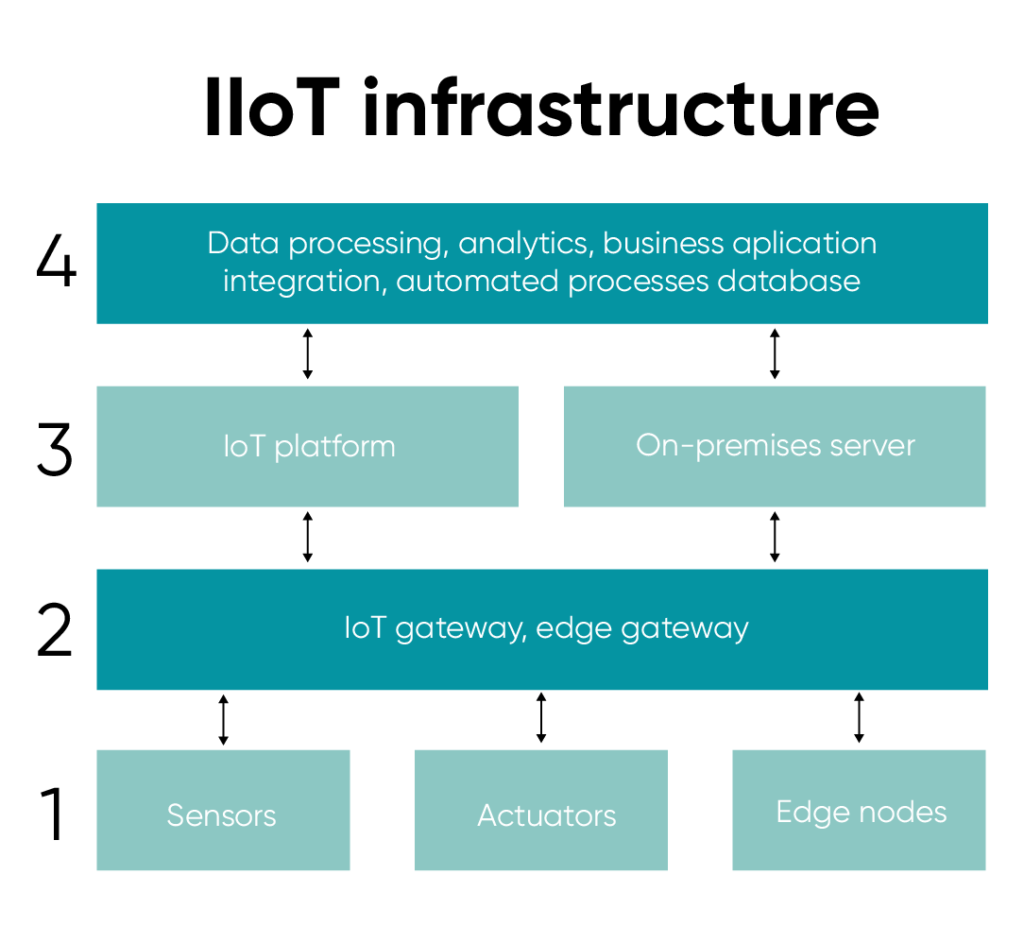

So how does IIoT, which is powering Industry 4.0, actually work? This goes way deeper than just having “smarter” machines that are always online. Yes, the machines will store and communicate the relevant metrics. But as evident in the diagram below, there is a lot of software and hardware infrastructure that is also needed to create a supply chain and comprehensive and scalable smart factory.

In layman’s terms, Industry 4.0 is all about harvesting data from the manufacturing ecosystems (machines, equipment, lines, etc.) and breaking it down to gain business intelligence and actionable insights. These can be implemented in a smart factory in real-time to improve manufacturing metrics across the board. Besides the obvious improvements this brings to transparency and traceability, manufacturing processes become more efficient, productive, economical, and scalable.

While most executives understand the Industry 4.0 basics and are familiar with all aforementioned terms, they can’t get started due to various technical and monetary constraints. Also, they are often invested in expensive legacy ecosystems or simply can’t afford the downtime that comes with replacing or upgrading their infrastructure. This is where digitalization via non-intrusive sensors enters the picture.

Implementing IIoT technology to harvest machine data is always going to be the ultimate first step in any factory looking to go smart, but like in many other things in life, it’s usually impossible to skip the crawling stage. A typical production floor is made up of dozens of expensive machines of different types, makes, and models. Replacing them with new and connected machines is a daunting task on many levels. Retrofitting digitalization technology is coming to the rescue today.

Did You Know?

As per a recent McKinsey Manufacturer Research Survey, 68% of the respondents cited that Industry 4.0 is a top priority for them.

It is now possible to install sensors in a non-invasive and safe manner outside any type of machine or equipment, regardless of type, make and model, to measure key performance metrics. These sensors, all connected to a local network, use multiple factors such as electrical current, temperature, humidity, vibration, sound, and more to create data. This real-time data is processed by proprietary software to generate actionable insights that can be leveraged to improve productivity and manufacturing efficiency in a smart factory.

The benefits of retrofitting IIoT into manufacturing machines are:

Get Started Fast – The primary benefit of these solutions is their plug-and-play nature. There is very little investment or installation cost involved. Companies can literally turn “smart” in just a few hours. They can transform slow and inefficient production floors into optimized and synchronized ecosystems. The results are almost immediate and start boosting the company’s bottom line within weeks.

Visibility and Transparency – Executives and managers can now monitor all key metrics via one centralized dashboard, locally and remotely. Also, employees on the shop floor and in the boardroom are all exposed to the same real-time data, which is unified across machines, shifts, production floors and manufacturing sites. Personalized alerts and reports via mobile and tablet around the clock make it easier to identify bottlenecks and optimize processes to improve productivity.

Fast and Secure – When using non-invasive sensors, hacking into machines and interfering with their performance is impossible. Hacking into the monitoring system will generate a lot of sensory information, with no impact on the continuity of manufacturing. Also, there is no risk of voiding machine warranty, as no digital connection is established between the monitoring system and the machine electronics.

Worker Engagement – Real-time asset monitoring is also a great way to boost worker engagement. More and more companies are installing large tracking screens on their premises so that workers can see what is really going on under the hood. This also helps them set collective goals and KPIs, while encouraging them to work together as a group to meet them.

All of the benefits mentioned here are serious performance boosters. Digitalization eventually allows smart factories to save money and resources, reduce labor, raw material and energy usage, and increase productivity. Getting access to data is only the first step in digital transformation. Once big data is available, there is no limit to the capabilities that can be gained, from predictive maintenance, through artificial intelligence and up to self-optimization.

Gone are the days when dozens of workers would toil around the clock to keep their workstations active, with managers and executives not really knowing much about their productivity. Advanced asset performance monitoring capabilities are now giving manufacturers the ability to improve productivity and achieve scalability with the help of big data and business intelligence to run a smart factory.

Only actionable insights into machine performance can help executives and managers optimize their manufacturing processes, improve productivity, and achieve profitability. Orthodox manufacturing practices are becoming a huge liability in today’s market. The transition to industry 4.0 and smart factories has to be gradual and incremental, with the first step being connectivity and digitalization of all assets in order to gain real-time data. Start your transformation now.