In the last century, the way maintenance is scheduled and conducted has changed significantly several times. The traditional approach was that of “fix things as they break”. This approach dominated for many years since the industry was not very complex or highly mechanized. After World War 2, the industry started to rely more and more on machines, which raised the importance of reducing equipment downtime. A new approach – “time based overhauling” – developed based on the assumption that components have a specific life time and would fail after reaching a certain age. Therefore, conducting maintenance on a planned schedule and replacing components before they reach their end of life, would prevent failures and downtimes.

The industry adopted this approach.

However, contrary to expectations, increasing the amount of preventive maintenance didn’t reduce the amount of failures or machine downtime for several reasons:

After analyzing 12 years of data, it was concluded that overhauls had little or no effect on overall reliability or safety. A new and modern approach has become dominant: “Reliability Centered Maintenance”. This approach balances between the two old approaches and combines 9 innovative principles:

Many industries adopted the modern Reliability Centered Maintenance approach and were now able to reduce the amount of maintenance conducted on each machine to the necessary minimum, and perform it only when it’s really required, based on equipment age and condition.

But how can one tell when is the right time to perform machine maintenance?

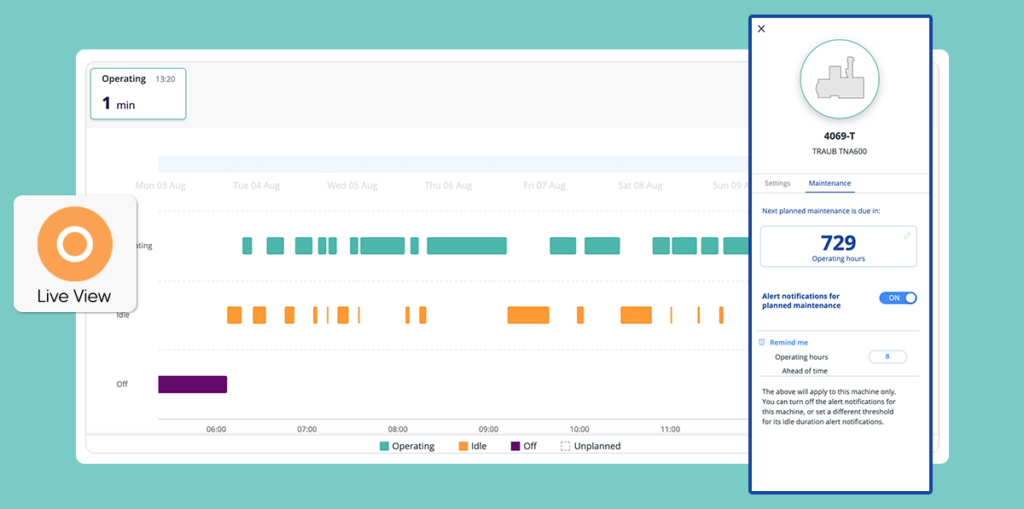

3d Signals has a solution for that. Beyond the live updates and business insights, the 3d Signals Asset Performance Monitoring solution enables to monitor and manage the next planned maintenance based on the actual working hours of the machine, and free the maintenance personnel from manual or paper tracking.

The maintenance tool provides full flexibility to meet a variety of needs: