2019 was a pivotal year for 3d Signals in more than one aspect, and we are now starting a new decade, ready for what we call “3d Signals – Season 2”. The transformation we went through is reflected in everything we are doing today, including our brand, and we would like to share the process and important milestones that brought us to this new and exciting starting line.

3d Signals was established in 2015 as an 4.0 enabler. The company raised $5M and worked with large manufacturing and utility companies to develop the product. In mid-2018, with many pilot projects but still no concrete business opportunity, a new CEO, Ariel Rosenfeld, was brought in.

The first thing Ariel did was visit numerous pilot partners to hear first-hand their feedback and their experience with the 3d Signals product. What he realized was, that although our goal – to help factories improve their efficiency – was the right one, the path we chose to achieve it – predictive maintenance – was too far and too soon for most factories. With all the hype around Industry 4.0, artificial intelligence and machine learning, it was hard to notice that most machines were not even connected to a network.

In a way, we were trying to teach our customers to run before they could walk.

This crystal-clear realization came during a meeting Ariel had with one of our pilot partners, SAMSON AG, a 112-year old company that specializes in valves and flow control. While realizing that our joint project is reaching a dead-end, Dr. Andreas Widl, SAMSON AG’s CEO shared his main pain point with Ariel – with 18 factories around the world, and hundreds of machines, he had no visibility into his shop floors, and therefore no data to help him improve his operations.

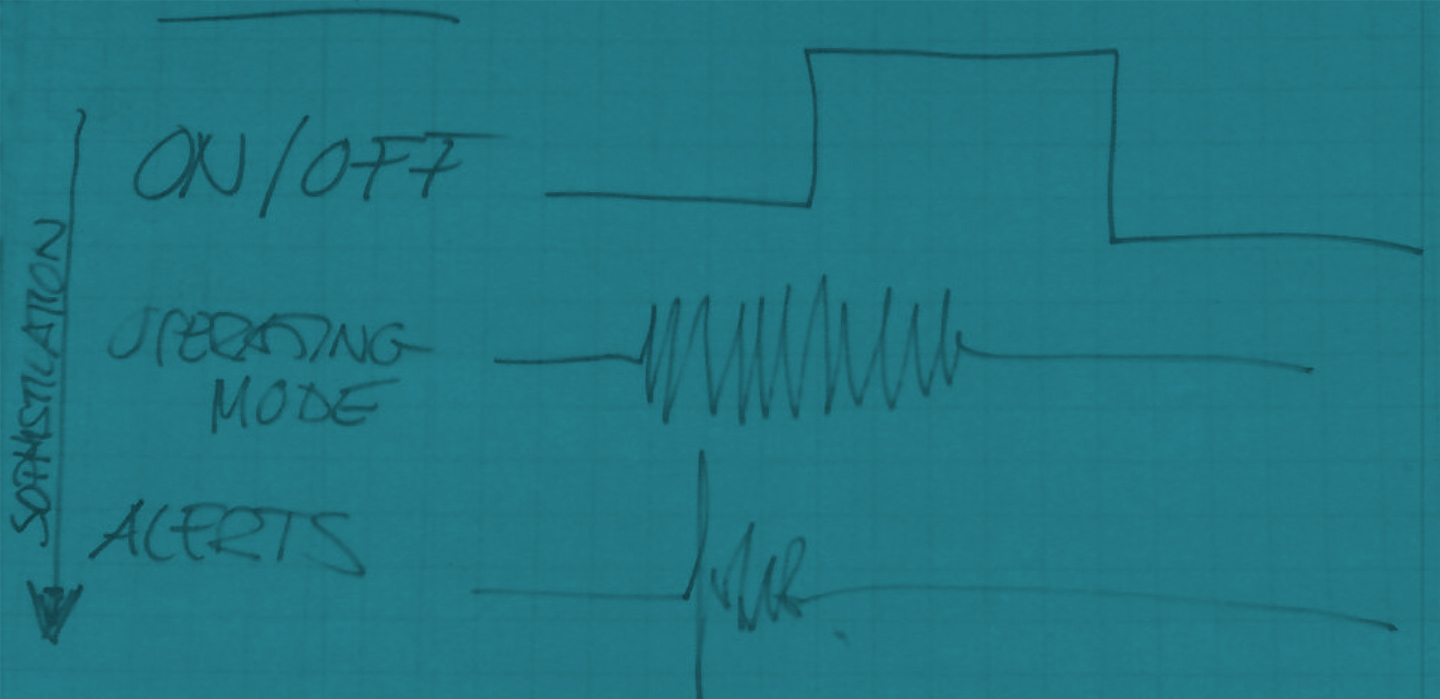

In that meeting Ariel and Dr. Widl sketched what has become our new roadmap – a plug & play factory digitalization solution that provides instant visibility and business intelligence, which can be translated into valuable and actionable insights.

SAMSON AG has since become a design partner of 3d Signals, and Dr. Widl sits on our advisory board. The company has our solution installed on more than 100 of their critical assets, achieving more than 50% added machine availability, a significant reduction in labor cost as a result of more productive shifts, and energy saving due to reduction of machine idle times.

Armed with a newfound understanding of factories’ needs and the direction we need to take, we went back to the drawing board, determined to recalibrate our solution. An internal decision was made – 2019 is going to be our year to implement a significant change to our product, and achieve meaningful results for us as a company and for our customers on their quest to improve machine efficiency by reducing downtime.

We are proud to report that during 2019 we achieved all that, and so much more:

All of the above, combined with the constant positive feedback we receive from our customers, stand as an undisputed proof to the real need for the 3d Signals solution, and the meaningful results it brings to factories in terms of efficiency improvement and operating cost saving.

As 2019 was coming to a close, another realization set in. We are a different company now, with a revamped product and a new strategy. We felt that this next chapter in our journey as a company should be reflected in our brand messaging and visual identity.

One sentiment that kept coming back in our discussions with our customers was ‘an amazing transformation’. They felt that our solution was transforming their factories from brownfield, disconnected operations to digital, visible ones, and that this transformation happened in an instant, with no effort on their side; almost as if done by magic. Their goal of becoming an Industry 4.0 factory of the future, which seemed unattainable before, has turned into a reality. They were achieving higher productivity and improved efficiency, while instantly turning their operations from sufficient to efficient.

The fact that we, 3d Signals, also went through a transformation ourselves as a company, added to our conviction that this should be the essence of our new identity.

And so, our new branding is all about an instant, almost magical transformation. From a no-data, no-visibility operation into highly efficient, data-driven management, with a simple, plug & play approach that seems almost too good to be true. We take a machine and transform it from the old world to the new world of Industry 4.0 in 58 minutes or less.

It is our strong relationship with our customers and partners that helped us better understand both the real needs and the true value we bring to factories – transforming them into Industry 4.0 factories of the future, and improving their operation through visibility and data.

We look forward to a new year and a new decade of helping factories all over the world achieve their full potential through an instant and meaningful digital transformation.